Production IT

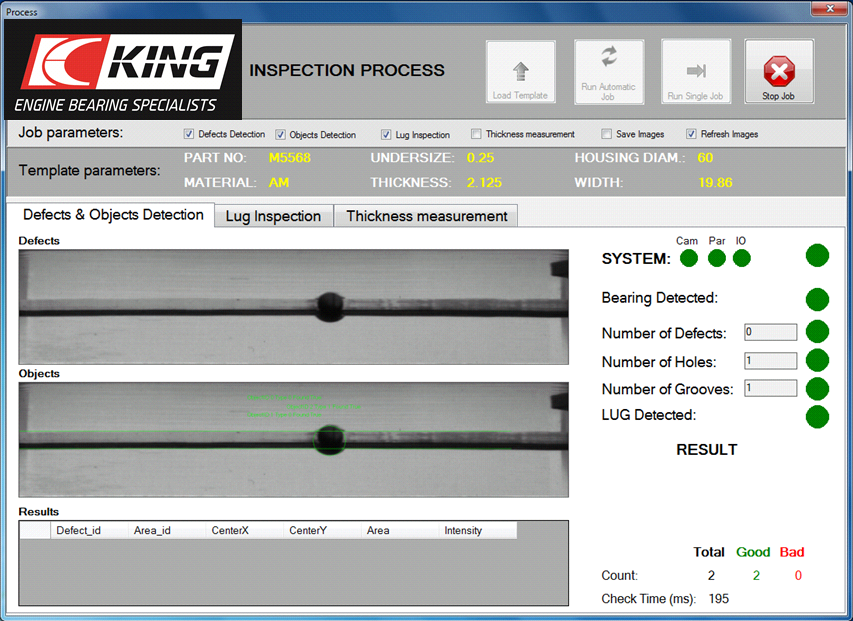

King has developed a variety of production IT processes to manage manufacturing (MES) and quality (QMS). These procesess are fully computurized and have allowed us to improve the efficiency and accuracy of our production lines.

Our systems give us the flexibility to adjust bearing features and geometry to conform to each application’s specific requirements.

King production IT systems include:

Document control — Electronic document control approach ensures that the correct revision(s) are the only ones available. The systems automatically issues: BOM (Bill Of Material) , Root Card, Control Plan, Product Drawings, etc.

Tool and gage management : KQMS™ indicates which gages throughout the facility are due for calibration. Because KQMS is an electronic system, related documentation such as gage prints, specifications and pictures are immediately available.

Integrated Measurements devices : measurement devices are directly connected to work stations and inspection inputs are automatically collected, directly from the inspection tools.

SPC online – KQMS system with embedded SPC tracks production time and quantities, and can electronically flag operators when a process is due for inspection. In addition, because this is linked to our gage tracking/management system, gage calibration is scheduled by frequency of use rather than an arbitrarily specified time frame.